Transforming Concepts into Reality with Precision and Excellence

Your Turn-Key Solution for Engineering, Prototyping, and Manufacturing Needs

Upload your files. Receive instant pricing. Order online.

Our Services.

Mix and match our wide range of sheet metal services to get your parts made exactly how you want them.

Laser Cutting

Base Lead Time: 1-2 Days

Bending

Base Lead Time: +1 Days

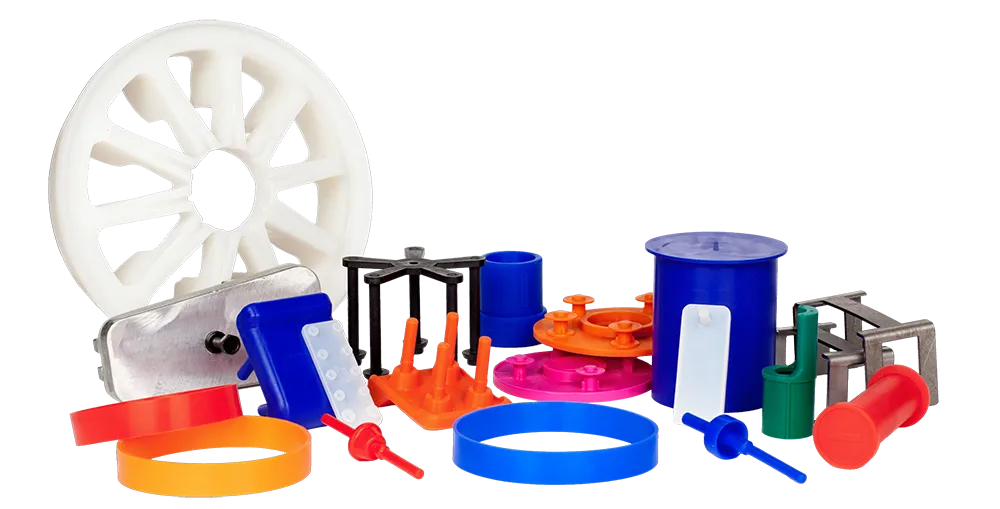

Injection Molding

Base Lead Time: +1 Days

Full Service Metal Fabrication

Base Lead Time: +1 Days

Conveyor Manufacturing

Base Lead Time: +1 Days

Electro-Mechanical Production & Assembly

Base Lead Time: +4-5 Days

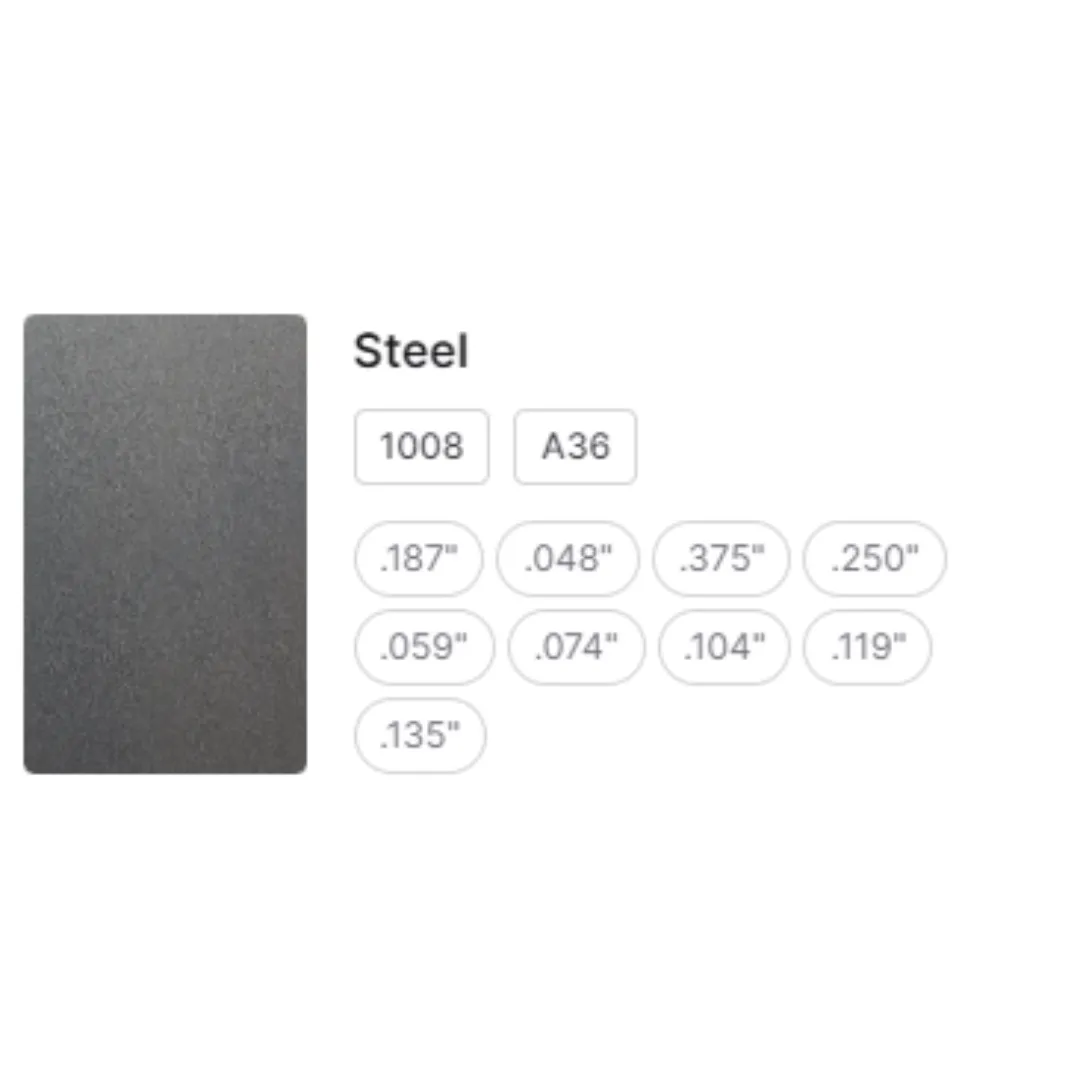

Industry Graded Materials

Select from a refined list of high performing materials, expertly picked to give you the best laser cutting and bending results

Get a Quote Instantly.

Upload your STEP file for an instant laser cutting quote using our intuitive online platform.

Quote in seconds, order in minutes, receive parts in days.

follow on social media for content and offers

Frequently Asked Questions.

Get your questions answered, if you can't find something your looking for, feel free to contact us.

What services does Fabworks offer?

Fabworks provides comprehensive contract manufacturing services, including engineering, prototyping, fabrication, injection molding, final assembly installation, and service. We specialize in turnkey manufacturing solutions, offering a hassle-free experience for our clients.

What is turnkey manufacturing, and how does Fabworks excel in it?

Turnkey manufacturing is an approach where a single contractor manages the entire production process, from design to delivery. Fabworks stands out in this field by offering end-to-end solutions, minimizing client involvement, and ensuring a seamless and efficient production cycle. We handle everything from design hand-off to final assembly, providing a singular point of contact and accountability..

What types of metal fabrication services does Fabworks provide?

Fabworks offers a full range of metal fabrication services, including MIG, TIG, and Stick welding for aluminum, carbon steel, stainless steel, and other metals. Our capabilities span from precision components to structural elements, catering to diverse industry needs.

How does Fabworks ensure precision in metal bending?

Fabworks utilizes CNC press brakes for bending metal with the highest precision. This technology allows us to control bending angle, plate thickness, width, and grade with unmatched accuracy, making it ideal for industries requiring accurately formed components, such as automotive and aerospace.

Can you provide examples of products manufactured using CNC press brakes?

Certainly! Fabworks manufactures precision-formed brackets, panels, and enclosures for various applications using CNC press brakes. These components meet stringent quality standards and are used in industries ranging from automotive to aerospace.

What are the benefits of laser cutting services offered by Fabworks?

Fabworks' laser cutting services provide remarkable precision down to a fraction of a millimeter. Our CNC technology ensures consistency and speed, making it suitable for creating detailed designs and large production runs. Additionally, laser cutting eliminates the risk of material distortion or warping, resulting in high-quality finished products.

How does Fabworks handle injection molding projects?

In injection molding, Fabworks utilizes modern processes with reciprocating screw technology to produce polymer products efficiently. We are a mid-tier supplier of polymer products, offering expertise in material selection, mold design, and production. Our re-usable molds and comprehensive capabilities make us a trusted partner for injection molding projects.

Can Fabworks customize conveyor systems for specific applications?

Absolutely! Fabworks specializes in conveyor manufacturing for material handling solutions. Whether you need conveyors for warehouses, manufacturing facilities, or distribution centers, we can tailor our solutions to meet your unique requirements.

How does Fabworks support electro-mechanical production and assembly projects?

Fabworks provides electro-mechanical production and assembly services, including the assembly of electrical cabinets, panels, and various electromechanical components. We offer expertise in producing belts, motors, and cells, ensuring efficient and reliable solutions for our clients.

What industries does Fabworks serve?

Fabworks serves a wide range of industries, including automotive, aerospace, electronics, construction, medical devices, and more. Our versatile capabilities and commitment to quality make us a trusted partner across diverse sectors.

We aim to simplify the production process and enhance client satisfaction.

Ready to experience precision manufacturing at its finest? Take the first step towards your next project by filling out our online form now! Let's bring your ideas to life with Fabworks.

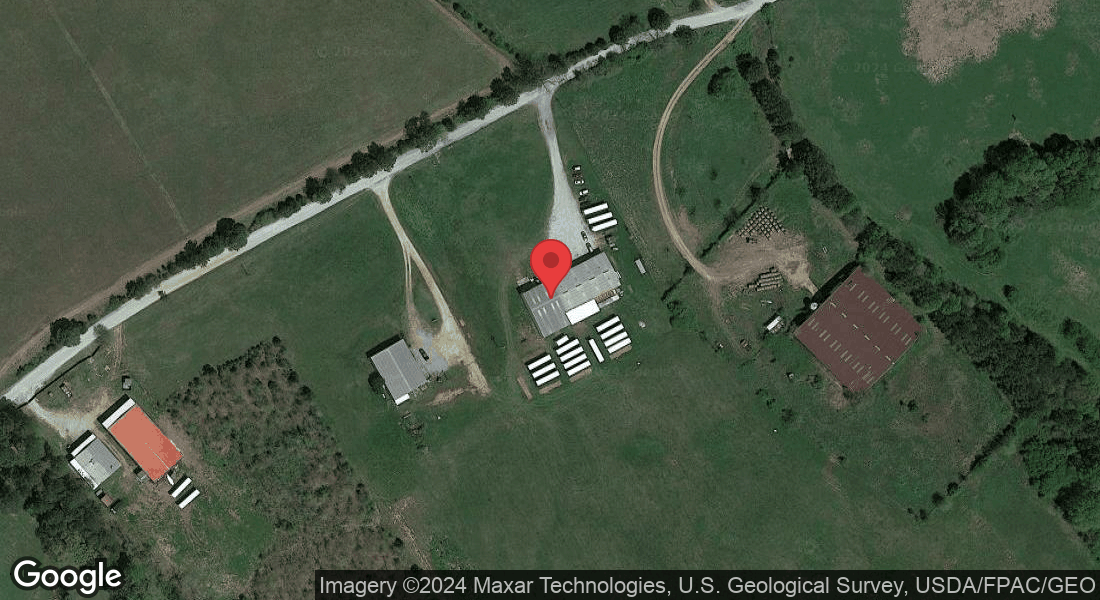

SHIPPING WITHIN THE UNITED STATES

HOME BASE: GEORGIA

Rooted in Georgia, Fabworks proudly extends its comprehensive manufacturing services across the United States.

Our commitment to innovation, quality, and customer satisfaction transcends geographical boundaries, ensuring that from coast to coast, businesses can access our engineering, prototyping, fabrication, and assembly services.

Leveraging advanced technology and a robust logistics network, we guarantee precision, efficiency, and timely delivery nationwide.

With Fabworks, distance is no obstacle to exceptional manufacturing solutions.

BUSINESS HOURS

Monday - Friday: 8:00AM - 4:00 PM

Saturday - Sunday: Closed

VISIT OUR OFFICE AT

1338 Ross Rd, Shady Dale, GA 31085